custom gas griddle supplier

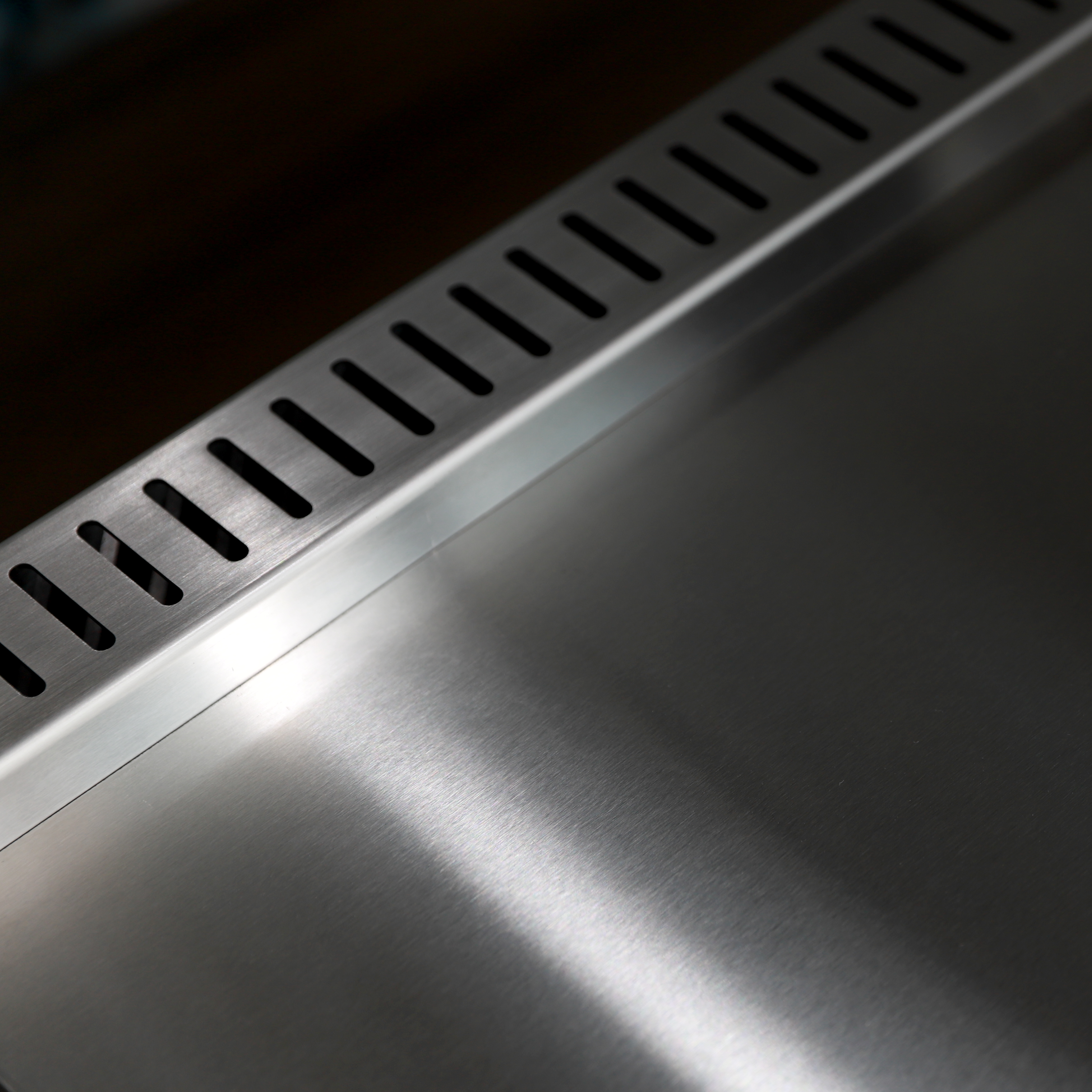

A custom gas griddle supplier stands as an essential partner in the food service industry, offering specialized solutions for commercial kitchens and restaurants. These suppliers provide state-of-the-art gas griddles designed to meet specific customer requirements, incorporating advanced temperature control systems and premium-grade stainless steel construction. The griddles feature precise heat distribution technology, ensuring consistent cooking results across the entire cooking surface. Modern custom gas griddles come equipped with electronic ignition systems, programmable controls, and safety features such as automatic shut-off mechanisms. These suppliers work closely with clients to determine optimal griddle sizes, ranging from compact 24-inch models to expansive 72-inch commercial units. The customization options extend to burner configurations, allowing for different temperature zones across the cooking surface. Additionally, these suppliers provide specialized surfaces, including chrome-plated options for reduced heat radiation and improved energy efficiency. Their expertise encompasses not only manufacturing but also installation support, maintenance guidance, and after-sales service, ensuring long-term customer satisfaction and equipment reliability.