gas griddle factory in china

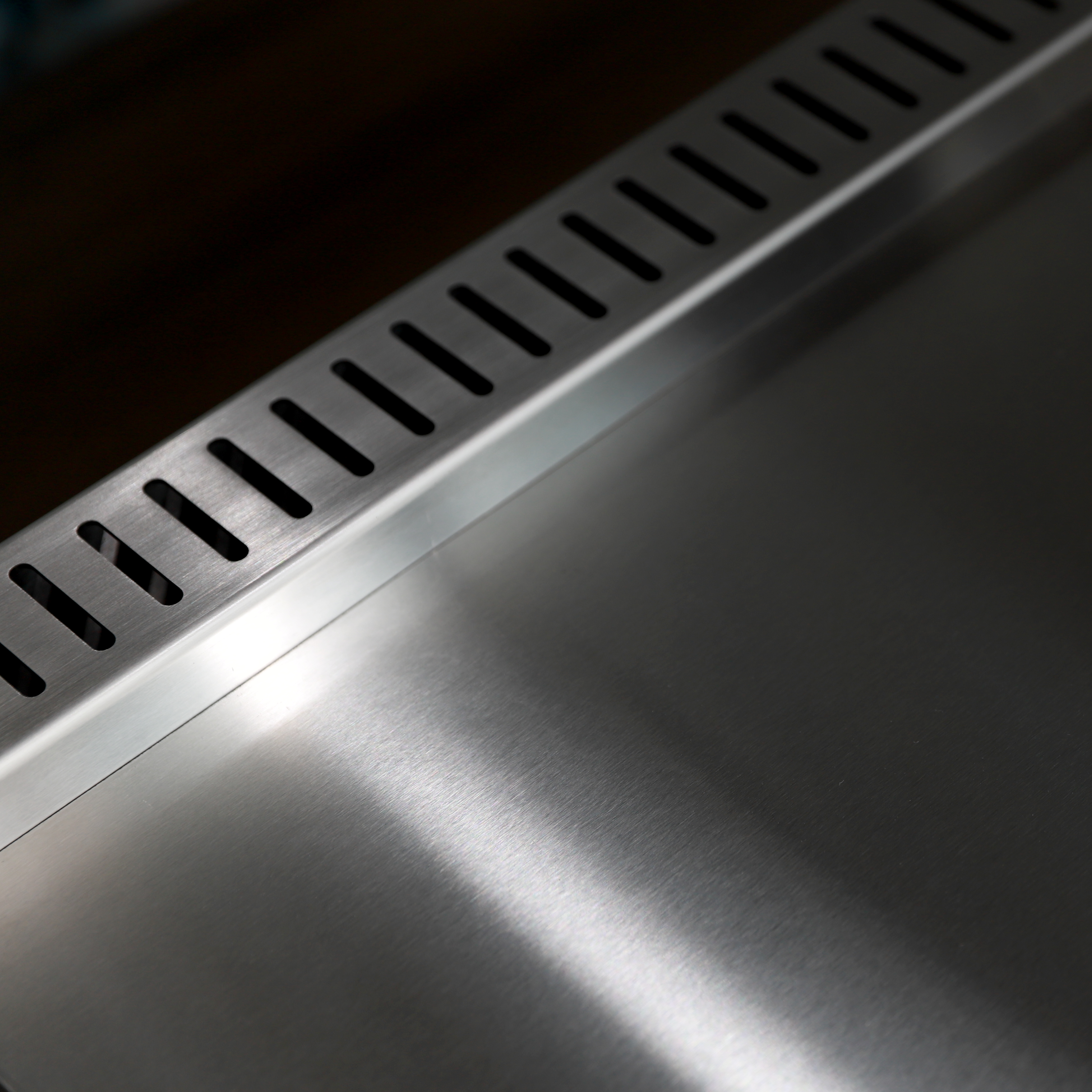

The gas griddle factory in China represents a cutting-edge manufacturing facility specializing in commercial cooking equipment. This state-of-the-art facility combines advanced production technology with strict quality control measures to produce high performance gas griddles. The factory utilizes automated production lines equipped with precision machinery and robotics to ensure consistent product quality. Their manufacturing capabilities include the production of various griddle sizes, from compact 24-inch models to expansive 72-inch commercial units. The facility incorporates advanced material processing techniques, including precision steel cutting, surface treatment, and thermal engineering to create durable, efficient cooking surfaces. Quality assurance protocols include rigorous testing of heat distribution, temperature control systems, and safety features. The factory's research and development department continuously works on innovating griddle technologies, focusing on energy efficiency, heat retention, and user friendly controls. Their production process adheres to international safety standards and environmental regulations, ensuring products meet global market requirements. The facility also maintains a comprehensive spare parts inventory and provides technical support for product maintenance and repairs.