gas grill manufacturer

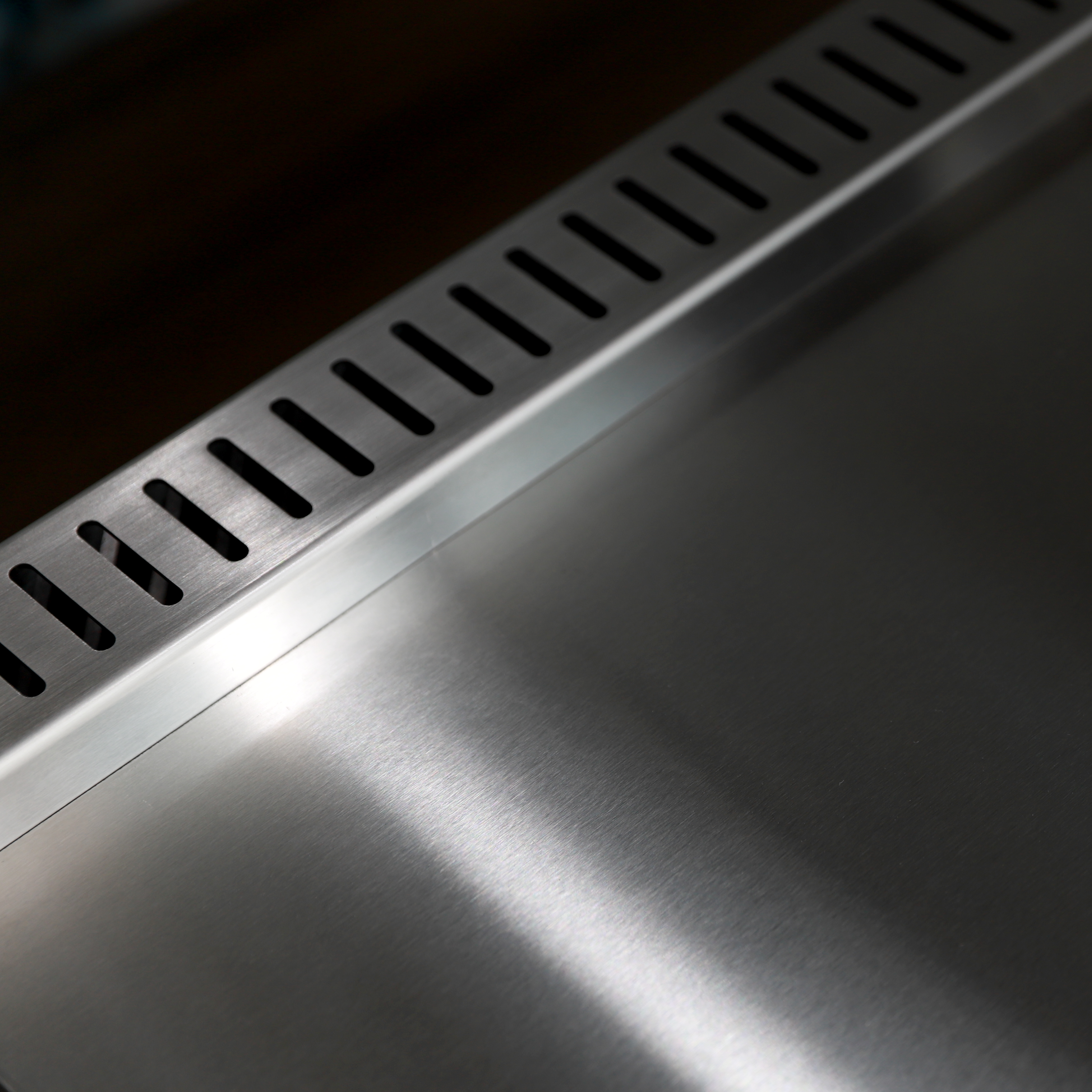

A gas grill manufacturer represents a cornerstone in the outdoor cooking industry, specializing in the design, production, and distribution of high-quality gas grilling systems. These manufacturers combine cutting-edge technology with innovative design principles to create grills that deliver consistent cooking performance and durability. Modern gas grill manufacturing facilities utilize advanced robotics and precision engineering to ensure each component meets strict quality standards. The manufacturing process encompasses everything from the selection of premium materials like commercial-grade stainless steel to the implementation of sophisticated temperature control systems and reliable ignition mechanisms. These facilities typically employ state-of-the-art testing procedures to verify heat distribution, fuel efficiency, and safety features. The manufacturing process also includes the development of specialized cooking surfaces, integrated temperature monitoring systems, and user-friendly control panels. Many manufacturers now incorporate smart technology features, allowing users to monitor and control their grills through mobile applications. The production line emphasizes both functionality and aesthetics, ensuring that the final products not only perform excellently but also enhance outdoor living spaces. Quality control measures are implemented at every stage, from component fabrication to final assembly, guaranteeing that each grill meets or exceeds industry standards for safety and performance.