griddle grill factory

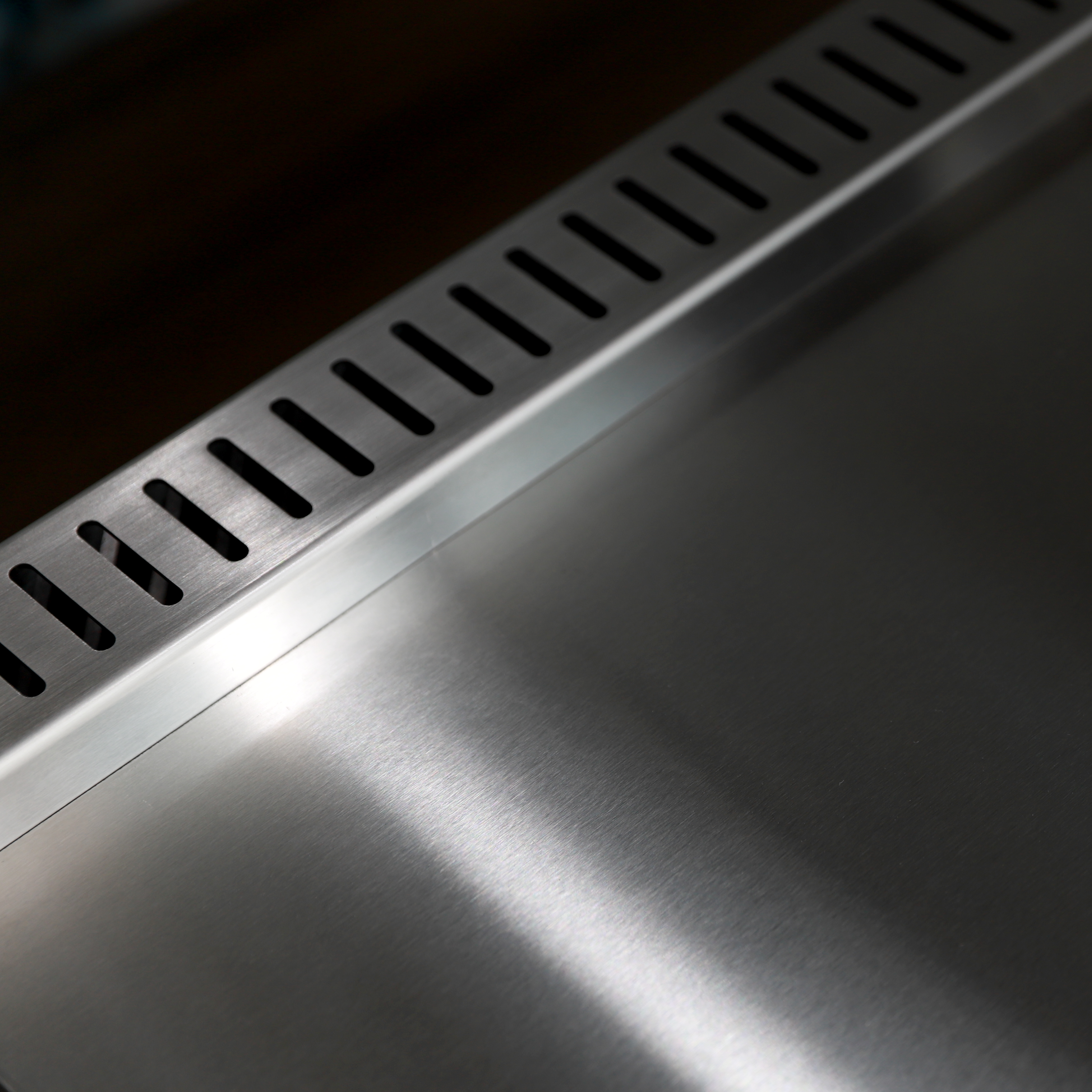

A griddle grill factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality commercial and residential cooking equipment. These facilities integrate advanced automation systems with precise quality control measures to create versatile cooking surfaces that combine the best features of traditional grills and flat-top griddles. The production line incorporates cutting-edge materials processing, including specialized coating applications and heat distribution technology, ensuring each unit meets rigorous performance standards. The factory employs sophisticated testing procedures to verify temperature consistency, durability, and safety compliance across all products. Modern facilities feature computer-aided design and manufacturing processes, enabling customization options while maintaining efficiency in mass production. The manufacturing process emphasizes environmental sustainability through energy-efficient operations and responsible material sourcing. Quality assurance protocols include multiple inspection points, from raw material verification to final product testing, ensuring each griddle meets international safety and performance standards. The facility's layout optimizes production flow, reducing assembly time while maintaining precise quality control at every stage.