When investing in commercial grilling equipment, businesses need to prioritize durability and performance to ensure their long-lasting BBQ grill delivers consistent results year after year. Whether you operate a restaurant, catering company, or outdoor event service, selecting the right grilling equipment can significantly impact your operational efficiency and food quality. A well-chosen long-lasting BBQ grill becomes a cornerstone of your kitchen operations, providing reliable service through countless cooking sessions while maintaining the high standards your customers expect.

Essential Construction Materials and Build Quality

Stainless Steel Construction Benefits

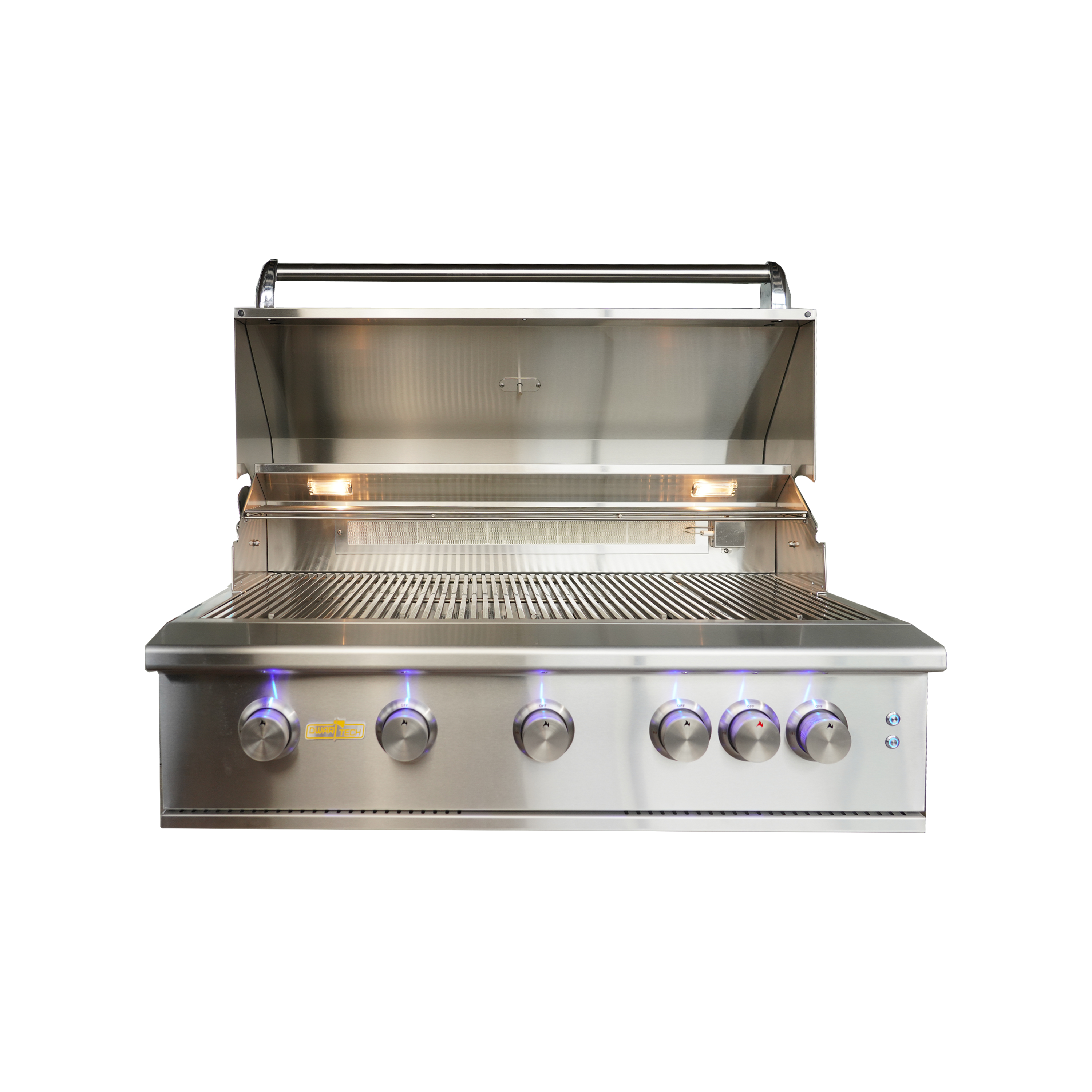

The foundation of any durable grilling system lies in its construction materials, with high-grade stainless steel leading the industry for professional applications. Premium stainless steel grades like 304 and 316 offer exceptional resistance to corrosion, heat damage, and daily wear from commercial use. These materials maintain their structural integrity even when exposed to extreme temperature variations and harsh cleaning chemicals commonly used in commercial kitchens.

Professional-grade stainless steel construction ensures that your investment maintains its appearance and functionality throughout years of intensive use. The non-porous surface of quality stainless steel prevents bacteria buildup and makes thorough cleaning more efficient, which is crucial for maintaining food safety standards in commercial environments. Additionally, stainless steel components resist warping and cracking that can occur with inferior materials under high-heat conditions.

Heavy-Duty Framework and Structural Integrity

Beyond surface materials, the internal framework of a long-lasting BBQ grill determines its ability to withstand constant use and transportation. Look for models featuring reinforced steel frames with welded joints rather than bolted connections, as welded construction provides superior strength and eliminates potential failure points. The frame should support not only the grill's weight but also the additional load of food, accessories, and regular handling by kitchen staff.

Proper structural design includes strategically placed support braces and a low center of gravity to prevent tipping during use. Quality manufacturers incorporate shock-absorbing elements that protect internal components from damage during transport or when the grill is moved between locations. This attention to structural detail ensures your equipment remains stable and safe throughout its operational lifetime.

Heat Management and Cooking Performance

Burner Technology and Heat Distribution

Advanced burner systems represent the heart of professional grilling performance, determining both cooking efficiency and fuel consumption. High-quality burners feature multiple flame ports that distribute heat evenly across the cooking surface, eliminating hot spots that can lead to uneven cooking results. Stainless steel burner tubes with precise engineering ensure consistent gas flow and optimal combustion for maximum heat output.

Professional burner designs incorporate features like flame tamers or heat tents that protect the burners from grease and food debris while redirecting heat for more uniform cooking temperatures. This protection extends burner life significantly while maintaining consistent performance. Some advanced systems include individual burner controls that allow operators to create different temperature zones for versatile cooking applications.

Temperature Control and Monitoring Systems

Precise temperature control separates professional equipment from consumer-grade alternatives, enabling consistent food quality that meets commercial standards. Built-in thermometers should provide accurate readings across the entire cooking surface, allowing operators to monitor conditions without lifting the lid and losing heat. Digital temperature displays offer more precise readings and often include programmable alerts for specific cooking requirements.

Advanced temperature management systems incorporate multiple monitoring points and can maintain set temperatures automatically through integrated control systems. These features reduce the skill level required for consistent results while freeing up staff to focus on other kitchen tasks. The ability to maintain precise temperatures also improves food safety compliance and reduces waste from overcooked or undercooked items.

Durability Features for Commercial Use

Corrosion Resistance and Weather Protection

Commercial grilling equipment faces constant exposure to moisture, grease, cleaning chemicals, and temperature extremes that can quickly deteriorate inferior materials. A truly long-lasting BBQ grill incorporates comprehensive corrosion protection through material selection and surface treatments that resist oxidation and chemical damage. Marine-grade stainless steel components and specialized coatings provide the highest level of protection against environmental factors.

Weather sealing becomes particularly important for outdoor installations or mobile operations where equipment may be exposed to rain, humidity, and temperature variations. Quality seals around control panels, gas connections, and access doors prevent moisture infiltration that could damage internal components or create safety hazards. Proper drainage systems ensure that water cannot accumulate in areas where it might cause corrosion or electrical issues.

Heavy-Duty Components and Hardware

Professional-grade hardware separates commercial equipment from residential alternatives, with heavy-duty hinges, latches, and control mechanisms designed to withstand frequent use and potential abuse. Industrial-strength gas valves and connections provide reliable operation and safety margins that exceed residential requirements. These components must maintain proper function even after thousands of operating cycles in demanding commercial environments.

Quality manufacturers use oversized bearings, reinforced mounting points, and premium materials for all moving parts to ensure smooth operation throughout the equipment's lifetime. Replaceable wear items like cooking grates and drip pans should be easily accessible and constructed from materials that can be thoroughly cleaned and sanitized according to health department requirements.

Maintenance and Serviceability Considerations

Accessibility for Cleaning and Maintenance

Efficient maintenance procedures directly impact the operational lifespan of commercial grilling equipment, making accessibility a crucial design consideration. Well-designed units feature removable components that can be thoroughly cleaned without specialized tools or extensive disassembly. Grease management systems should be easily accessible and designed to prevent overflow or backup that could create fire hazards or unsanitary conditions.

Professional equipment incorporates smooth surfaces and minimal crevices where grease and debris can accumulate, making daily cleaning more efficient and thorough. Removable cooking surfaces and drip pans allow for proper sanitization in commercial dishwashing systems, ensuring compliance with food safety regulations. Quick-disconnect features for gas lines and electrical connections enable easy removal for deep cleaning or service access.

Replacement Parts Availability and Service Support

Long-term value depends heavily on the availability of replacement parts and quality service support from the manufacturer. Established manufacturers maintain comprehensive parts inventories and provide detailed service documentation that enables quick repairs and minimal downtime. Standardized components and clear part numbering systems simplify ordering and reduce the risk of incorrect replacements.

Consider manufacturers that offer comprehensive warranties, training programs for maintenance staff, and technical support resources. Local service networks provide faster response times for critical repairs, while online resources can help troubleshoot minor issues without requiring service calls. The total cost of ownership includes not just the initial purchase price but also ongoing maintenance and support costs throughout the equipment's operational life.

Safety Features and Compliance Standards

Gas Safety Systems and Leak Detection

Commercial gas grilling equipment must incorporate multiple safety systems to protect operators and comply with local fire and safety codes. Automatic shut-off valves prevent gas flow when pilot lights are extinguished, while pressure regulators maintain consistent gas pressure regardless of supply variations. High-quality safety systems include redundant protection mechanisms that provide backup safety measures if primary systems fail.

Professional installations often require gas leak detection systems that can automatically shut off gas supply and trigger alarms if dangerous concentrations are detected. These systems integrate with building management systems and emergency response protocols to ensure rapid response to potential hazards. Regular testing and calibration of safety systems maintains their effectiveness and ensures continued compliance with evolving safety standards.

Fire Prevention and Suppression Integration

Grease fires represent the primary fire hazard in commercial grilling operations, making effective fire prevention and suppression capabilities essential safety features. Quality equipment includes grease management systems that minimize accumulation and provide safe disposal pathways for cooking byproducts. Automatic fire suppression systems can detect and extinguish fires before they spread beyond the cooking area.

Proper ventilation integration ensures that combustion products and cooking vapors are safely removed from the cooking area, reducing fire risk and maintaining air quality. Commercial-grade ventilation systems must coordinate with grill operation to provide adequate airflow without creating downdrafts that could affect burner performance or safety systems.

Energy Efficiency and Operating Costs

Fuel Consumption Optimization

Operating costs represent a significant portion of total ownership expenses for commercial grilling equipment, making fuel efficiency a critical selection criterion. Advanced burner designs and insulation systems reduce gas consumption while maintaining cooking performance, directly impacting profitability over the equipment's operational lifetime. Precise flame control and heat distribution minimize wasted energy and improve cooking consistency.

Energy-efficient designs incorporate features like wind shields, thermal barriers, and optimized combustion chambers that maximize heat transfer to food while minimizing losses to the environment. These improvements can reduce fuel consumption by twenty to thirty percent compared to basic commercial units, providing substantial savings over multiple years of operation. Smart control systems can further optimize energy use by adjusting burner output based on actual cooking requirements.

Operational Efficiency Features

Productivity enhancements reduce labor costs and improve service speed, contributing to overall operational efficiency beyond just fuel savings. Fast preheat times allow quicker response to customer orders, while even heat distribution reduces cooking times and improves food quality consistency. Multiple cooking zones enable simultaneous preparation of different menu items at their optimal temperatures.

User-friendly controls and automated features reduce the skill level required for consistent results, enabling cross-training of kitchen staff and reducing dependence on specialized grill operators. Digital displays and programmable settings help maintain consistency across different shifts and operators, ensuring that food quality remains constant regardless of who operates the equipment.

FAQ

What is the typical lifespan of a commercial-grade BBQ grill?

A high-quality commercial BBQ grill can operate reliably for ten to fifteen years with proper maintenance and care. The actual lifespan depends on usage intensity, maintenance quality, and environmental conditions. Professional-grade equipment with stainless steel construction and heavy-duty components typically outlasts residential alternatives by three to four times, making them more cost-effective despite higher initial investment.

How often should commercial grilling equipment undergo professional maintenance?

Professional maintenance should be performed quarterly for high-volume operations, with monthly inspections of safety systems and gas connections. Daily cleaning and basic maintenance by kitchen staff extends equipment life and ensures optimal performance. Annual comprehensive inspections by qualified technicians help identify potential issues before they become costly repairs or safety hazards.

What safety certifications should businesses look for in commercial grilling equipment?

Look for equipment certified by recognized testing laboratories like UL, NSF, or CSA that verify compliance with commercial safety standards. Gas equipment should meet ANSI standards for commercial appliances, while electrical components must comply with local electrical codes. These certifications ensure that equipment meets professional safety requirements and may be required for insurance coverage and regulatory compliance.

Can commercial BBQ grills be used in mobile food service applications?

Many commercial BBQ grills are specifically designed for mobile applications with reinforced frames, secure mounting systems, and vibration-resistant components. Mobile units require additional safety features like automatic shut-off systems and secure gas line connections that can withstand transportation stresses. Check local regulations regarding mobile food service equipment, as requirements vary by jurisdiction and may require specific certifications or modifications.

Table of Contents

- Essential Construction Materials and Build Quality

- Heat Management and Cooking Performance

- Durability Features for Commercial Use

- Maintenance and Serviceability Considerations

- Safety Features and Compliance Standards

- Energy Efficiency and Operating Costs

-

FAQ

- What is the typical lifespan of a commercial-grade BBQ grill?

- How often should commercial grilling equipment undergo professional maintenance?

- What safety certifications should businesses look for in commercial grilling equipment?

- Can commercial BBQ grills be used in mobile food service applications?